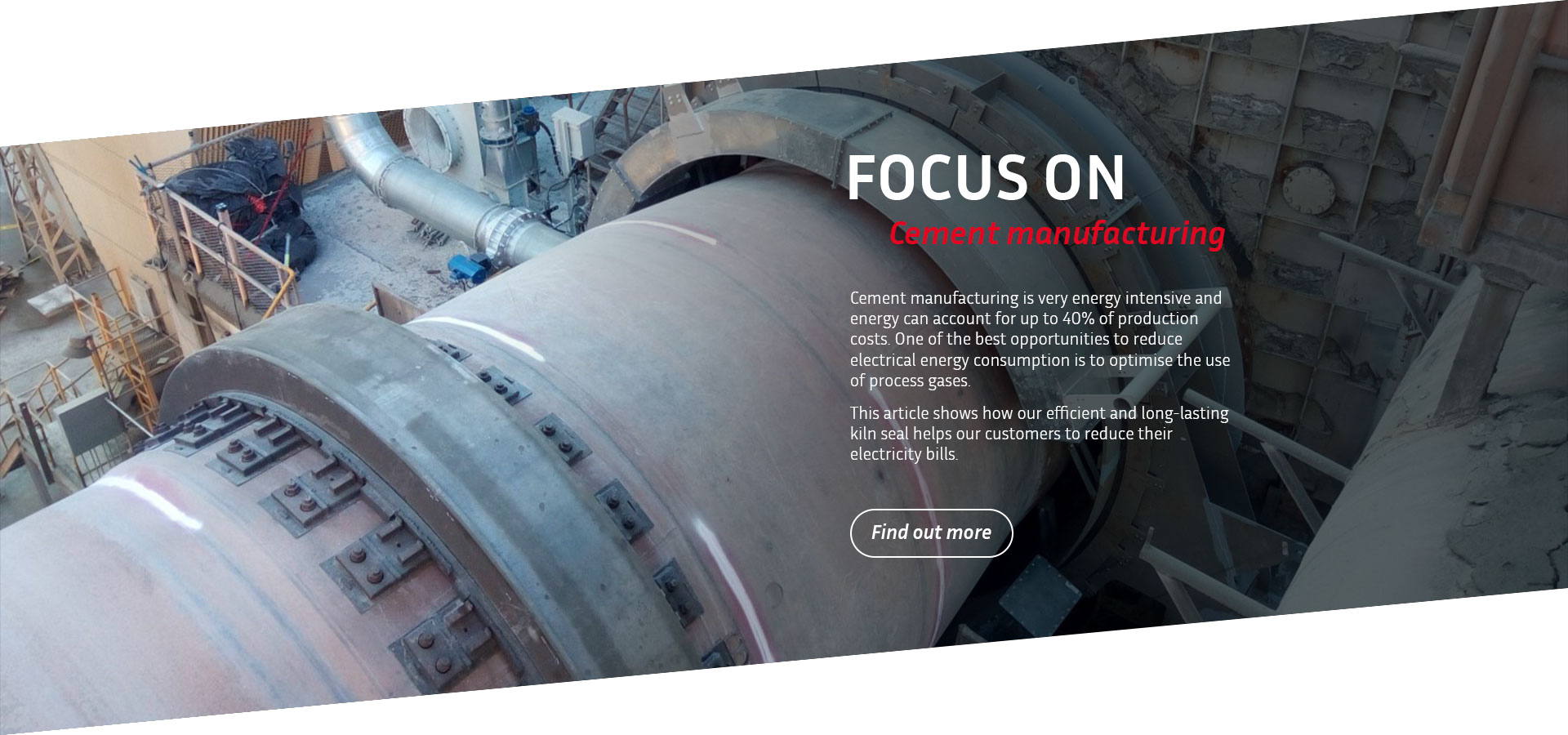

With more than 40 years of experience, our Cement Department has developed a range of solutions to optimise the various stages of production in cement plants.

Our team is supported by 2 engineering and design departments – Mechanical & Electrical/Automation – who have a perfect knowledge of this specific industry and who tailor solutions, both innovative and proven, to meet the various challenges faced by our customers.

We are recognised worldwide for our state-of-the-art equipment which improves the quality of the finished product and reduces production costs and environmental impact.

Our process control analysers – high frequency control of loss on ignition on hot meal or cement, free lime in clinker, gypsum/limestone additions or cement particle size, as well as our centralised automatic laboratories (Autolab) – sampling, transport, preparation and analysis systems – are used by all the major players in the cement industry on the five continents.

Our graphite slabs kiln seals are unrivalled in their efficiency and low maintenance requirements.

A reliable kiln inlet gas sampling and analysis system, a grinding balls sorter and a wide range of sensors and detectors complete our solutions for optimising the operation of our customers’ cement plants.

Our department designs and manufactures lump breakers, loading spouts for tankers and tippers.

Our loading trolleys allow to increase the loading rates by filling the trucks on several ports without moving the truck.

With over 40 years of experience in this field, our equipment is recognized as robust and reliable, meeting the most demanding requirements of our customers.

A full range of level sensors is available to meet all applications and a contactless solution is particularly suitable for demanding conditions. A reliable solution, not affected by dust content, is also available for level measurement.

Our rotation controller, consisting of a very robust casing, protects the inductive sensors and increases their lifetime while drastically reducing false detections.

Operation of ball mills can be optimized with our “Orelso” electronic ear solution, which measures the noise level in the mill and allows its filling to be adjusted in real time.

-

The Cement Department for the needs of cement manufacturers.

-

The Color & Vision Department for mines, quarries, sugar and sweeteners factories.

-

The Bulk Solids Department for the mining and mineral industries as well as more generally for the Solid Bulk industries (steel industry, food industry, pet food, waste treatment, chemical industry…).