to analysis

The quality and accuracy of an analysis depends on how the sample is collected in the process. Pierre Gy (founder of the Theory of Sampling) said: “At primary sampling, biases can be up to 1,000%, up to 50% at secondary sampling, while they almost never exceed 0.1 to 1% at analysis”.

The economic arguments for representative sampling are numerous, some examples are presented in this article.

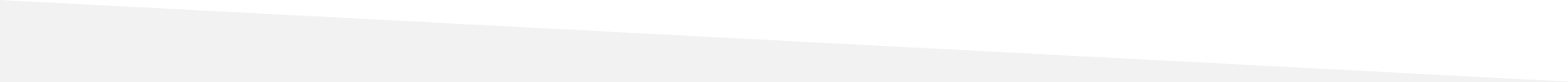

his is why ITECA has been offering for more than 40 years complete sampling, sample preparation and sample transport, as well as centralized laboratories in accordance with international sampling standards and Theory of Sampling (TOS). When such high levels of representativeness are not required, our sample-takers are perfectly suitable for mineral industry processes.

Technical devices can be classified in two categories:

Equipment designed and sized in accordance with the Theory Of Sampling (TOS) or sampling standards to ensure that the samples obtained are representative.

Equipment collecting material from the stream that is not designed in accordance with the Theory Of Sampling (TOS) or sampling standards. The representativeness of the sample is not guaranteed.

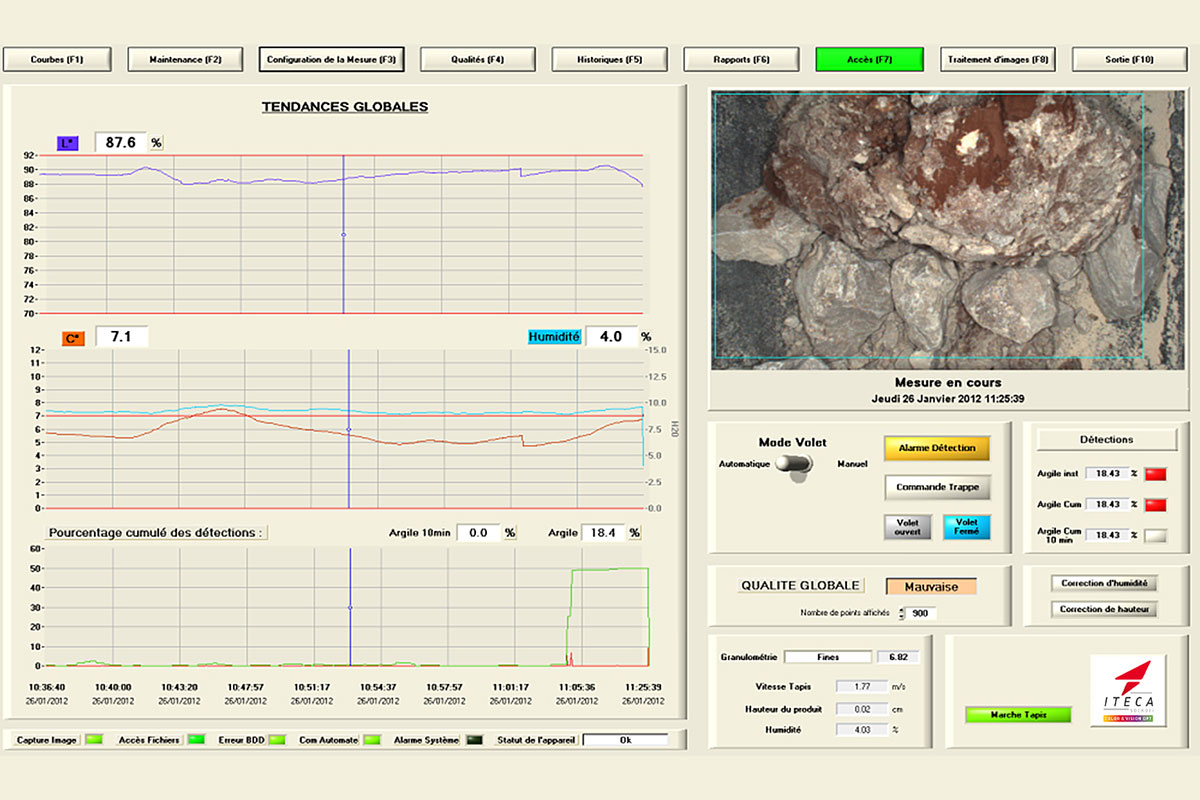

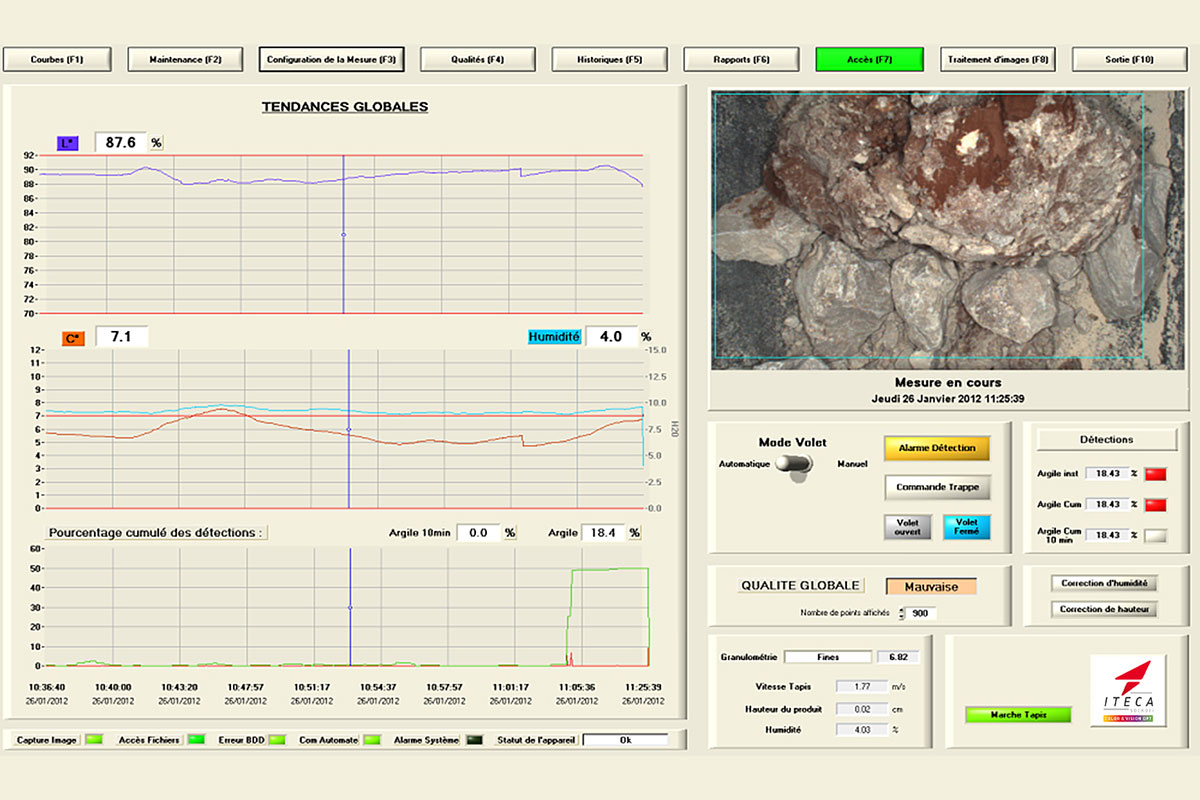

We present our range of on-line control systems, the large majority being based on colour calibrated image treatment and analysis. They are suitable for various sizes, depending on whether they are installed in a quarry for managing the stock piles, at the plant for controlling the blending recipes or on slurry for regulating flottation process.

High precision at-line measurement systems, based on spectral analysis of very fine powders samples of a few microns, are also proposed.

Whether it is through on-line image analysis or on laboratory samples, our measuring systems detect any type of coloured contaminants (clay, coal, etc). They may then be automatically deviated to avoid any contamination, ensuring constant quality compliant with customer specification and reducing manual sorting operation.

Various particle size distribution technologies are proposed depending on the application and the particle range to be analyzed:

- Real time contactless optical triangulation

- At-line automatic sieving

In both cases, thanks to our systems communication skills, the plant PLC use reliable dynamic measurements to optimizing production process parameters.

A full range of level detectors suitable for all applications in the mineral and mining industry including a contactless solution particularly designed for tough conditions.

A reliable solution, not affected by dust content, is also available for level measurement.

Our rotation controller, consisting of a very robust casing, protects the inductive sensors and increases their lifetime while drastically reducing false detections.

Operation of ball mills can be optimized with our “Orelso” electronic ear solution, which measures the noise level in the mill and allows its filling to be adjusted in real time

Our equipment is recognized as robust and reliable, meeting the most demanding requirements of our customers.

We present our range of on-line control systems, the large majority being based on colour calibrated image treatment and analysis. They are suitable for various sizes, depending on whether they are installed in a quarry for managing the stock piles, at the plant for controlling the blending recipes or on slurry for regulating flottation process.

High precision at-line measurement systems, based on spectral analysis of very fine powders samples of a few microns, are also proposed.

Whether it is through on-line image analysis or on laboratory samples, our measuring systems detect any type of coloured contaminants (clay, coal, etc). They may then be automatically deviated to avoid any contamination, ensuring constant quality compliant with customer specification and reducing manual sorting operation.

Various particle size distribution technologies are proposed depending on the application and the particle range to be analyzed:

- Real time contactless optical triangulation

- At-line automatic sieving

In both cases, thanks to our systems communication skills, the plant PLC use reliable dynamic measurements to optimizing production process parameters.

A full range of level detectors suitable for all applications in the mineral and mining industry including a contactless solution particularly designed for tough conditions.

A reliable solution, not affected by dust content, is also available for level measurement.

Our rotation controller, consisting of a very robust casing, protects the inductive sensors and increases their lifetime while drastically reducing false detections.

Operation of ball mills can be optimized with our “Orelso” electronic ear solution, which measures the noise level in the mill and allows its filling to be adjusted in real time

Our equipment is recognized as robust and reliable, meeting the most demanding requirements of our customers.

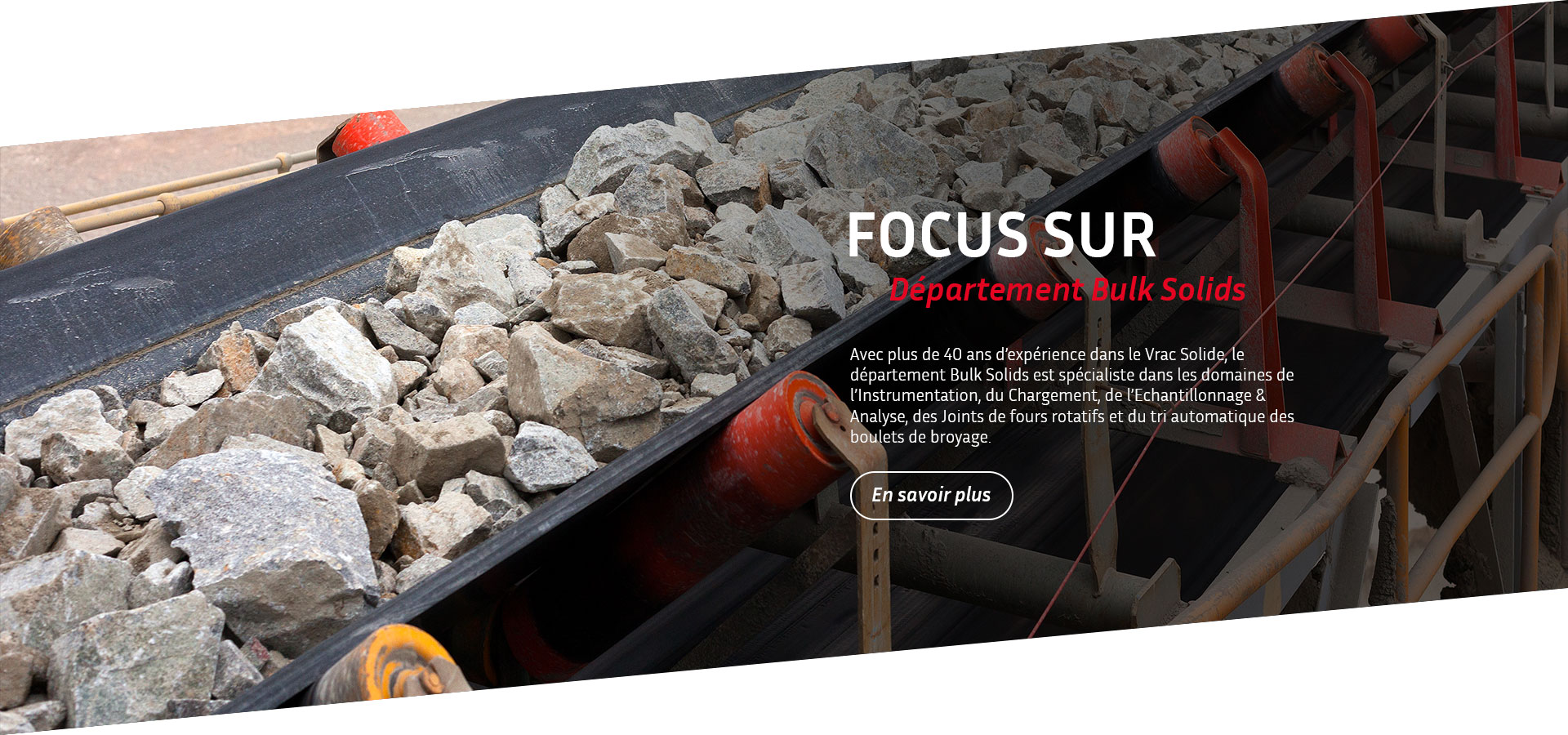

Our graphite slabs kiln seals are unrivalled in their efficiency and low maintenance requirements. They are designed for a large range of rotary kilns, calciners and dryers.

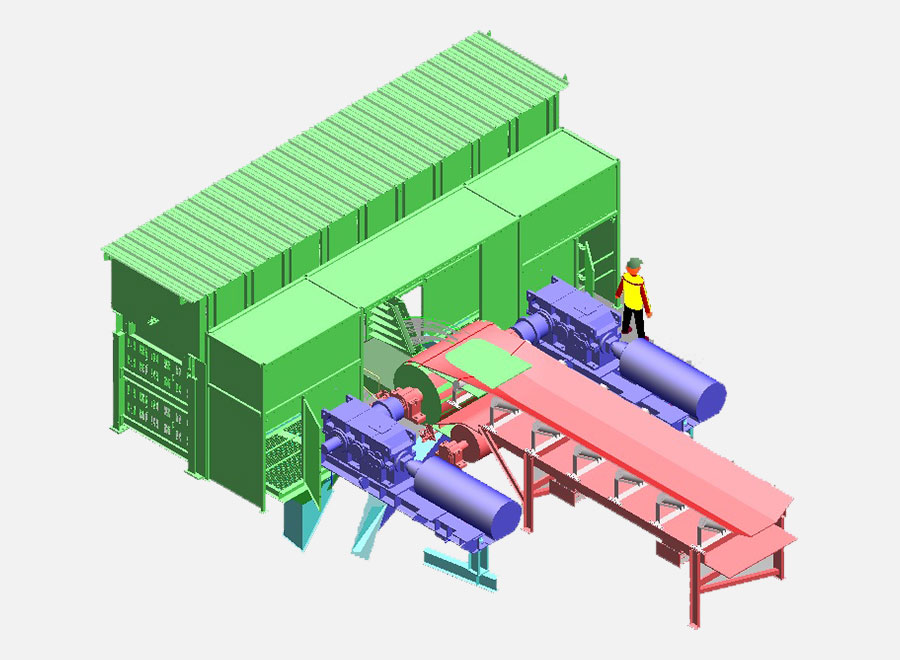

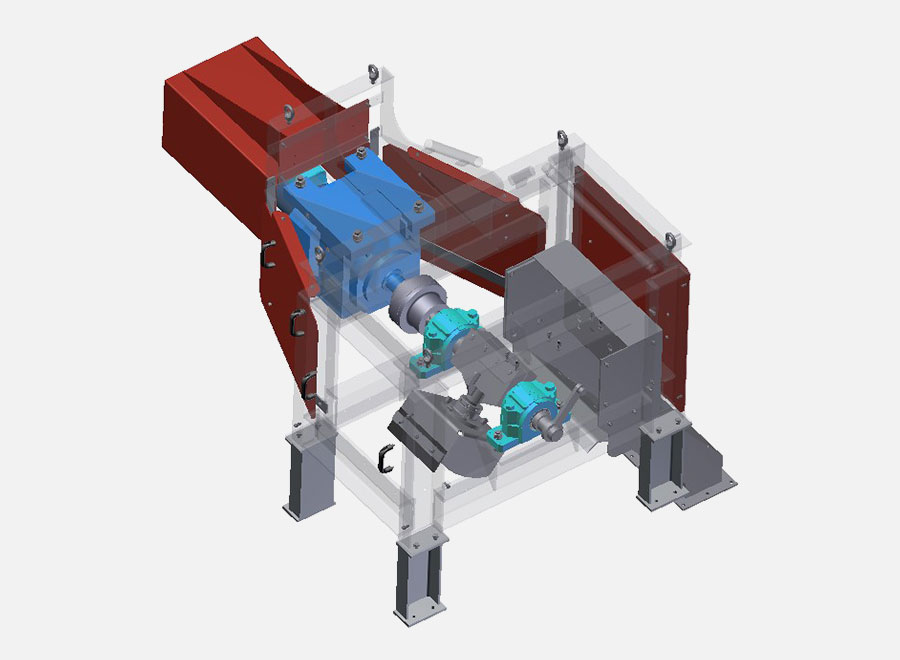

Our department designs and manufactures lump breakers, loading spouts for tank-trucks, and open-trucks, as well as a special loading spout for both types of truck.

Our loading trolleys allow to increase the loading rates by filling the trucks on several ports without moving the truck.

Our grinding ball sorting machine allows the automatic sortingof grinding balls into up to 10 different classes while eliminating of dust, non-spherical and broken balls.